|

|

||||||||||

|

PSW Spray booths Limited is a newly formed sister company to Pneumatic services who have supplied finishing services and equipment exclusively for over 40 years. We are pleased to announce with the formation of PSW Spraybooths Limited, our diversification into the field of spraybooth and sheet metal manufacture and supply. This move represents a considerable investment for us and our aim is to ensure that we are able to offer the complete range of spraybooths, with high quality of spraybooth manufacture, quick deliveries and service as customers have come to expect over the last 40 years. We would also like to take this opportunity to inform you of the other services that we offer

Services

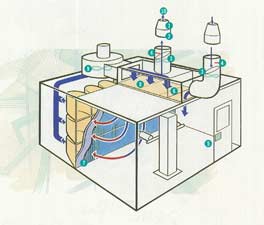

MEETING ENVIRONMENTAL LEGISLATION Spraybooth systems are subject to the strictest environmental and health at work legislation. Any infringement can lead to heavy fines and closure of production. Furthermore, proposed UK and European regulations are even tougher. Full compliance with existing and foreseeable legislation is essential. As leading specialists in spraybooth design we have extensive experience meeting these exacting demands. ASSESSING ENVIRONMENTAL IMPACT For greenfield projects or extending an existing facility, PSW experts will carry out detailed surveys and feasibility studies to determine the optimum system to meet production and finish specifications as well as comply with existing EPA regulations (Environmental Protection Act 1990) and proposed legal requirements. Every factor will be taken into account such as the type and volume of material used, whether it is solvent based, water borne, high solids or a two component paint and whether it is a high output or intermittent finishing process.

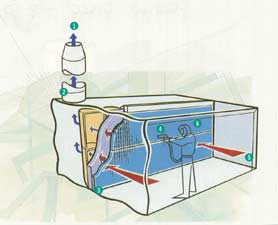

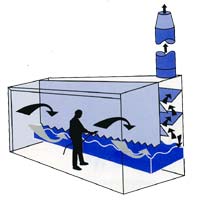

The Nopump system is world famous for its efficiency and reliability. As the name suggests there is no pump or associated pipework or nozzles to become clogged. High velocity air is drawn across the water in the bottom of the booth, producing violent agitation. The turbulent liquid is then circulated with abrupt changes in direction creating a constant scrubbing effect on the pain particles. This action causes them to break down and the pigment sinks to the bottom as a non-sticky, easy to dispose of silt. Automatic monitoring using special depression control valves ensuring the correct water level. The time between major clean-outs is dramatically extended and may only be needed at the annual shutdown. As there is no equipment mounted outside nor any need for bulky settling tanks, the booth is very compact and takes up minimum floor space. The unique. Virtually maintenance-free, Nopump is the preferred water wash spraybooth in paint shops world-wide. |

||||||||||

Re-Circulating

Booths

Re-Circulating

Booths

Dry

Filter Booths

Dry

Filter Booths Manufacture

supply and installation

Manufacture

supply and installation  Spraybooth

servicing

Spraybooth

servicing  NOPUMP

WATER WASH SPRAYBOOTHS

NOPUMP

WATER WASH SPRAYBOOTHS